CERINNOV Group is pleased to announce the completion of the installation of an impressive roller kiln at the CERAQUITAINE production facility in the south west of France.

After one year of project, the kiln is now about to be fully commissioned. CERAQUITAINE is a French international manufacturer of various refractories products used in different industrial sectors such as tableware, sanitaryware, kiln accessories, technical ceramics, automotive, tiles, glass and more.

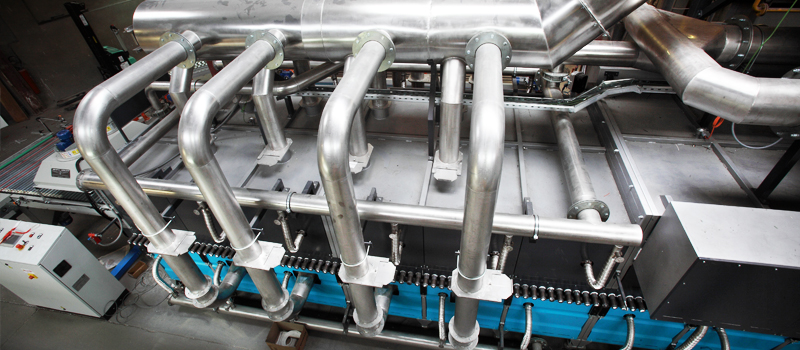

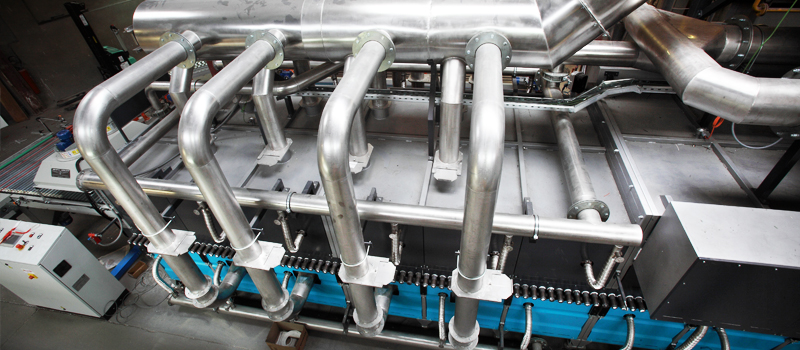

This kiln is dedicated to the fast firing of refractory slabs, loaded automatically and directly on the kiln rollers. The full equipment, manufactured by CERAMIFOR, a thermal division of CERINNOV Group, is a roller type, gas fired, 45 meters long including 26 meters of firing area, a maximum working temperature of 1450°C and is made with a hybrid insulation design: fiber for the upper parts, bricks for the lower parts.

The ceramic fiber module design is based on stack-bond assembly which allows to benefit from the fiber technical advantage without suffering from the risk of particle pollution.

Heat recuperation is installed at different levels: from the exhaust fumes for preheating combustion air injected in the preheating zone burners, and from the rapid cooling zone for preheating combustion air in the high temperature zone burners. In addition, a dryer installed in line before the firing area is heated with hot air coming from the kiln cooling zone, for optimized energy management. The modular design of the kiln allows for the possibility of a length increase in the future by adding new modules.

With this new high efficiency kiln installed on French soil, CERINNOV group, based in France and mainly export-oriented, is proud to contribute to the consolidation of the French industry and its know-how #LaFrenchFab.

CERAQUITAINE CEO’s own words best expresses customer satisfaction:

” CERAQUITAINE wishes to thank CERINNOV Group team, who took up the challenge for the construction of its new, high temperature, firing line. Despite an exceptional sanitary situation, they were able to adapt themselves with professionalism. “